General FAQ

Click any question to see the answer.

Product/Application Specific FAQ

Click any question to see the answer.

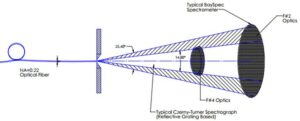

1. Resolution is not always the key criteria when specifying a spectrometer. Rarely in nature to you find two substances that have peaks which are ‘tightly’ close to each other, and you be the one tasked to resolve them. Think again before you specify that high spectral resolution or the high pixel count detector. 2. Throughput is not only f/#, but also needs to be matched to the spectrometer input. The f/# has no information on source, image or detector. If the f/# of the beam from the fiber is increased to match the acceptance f/# of the spectrograph/monochromator, the beam size on the slit increases and less light enters the spectrograph monochromator. The term optical “etendue” gives truer sense of what is attainable and what is not as is described in the following drawing.

3. It pays to be cool. Cooling the CCD/InGaAs reduces the dark current dramatically. The dark noise typically drops to half when the temperature of the CCD detector chip drops every 10°C for CCD or 7°-8°C for InGaAs. Advancements in semiconductor technology over the last 30 years has increased the availability of thermal electrical cooler chips, created improvements in hermetical sealing and long life vacuum processes, and allowed for the development and use of thermoelectrically cooled detectors as a replacement for cumbersome Liquid Nitrogen based approaches. 4. All detectors are not the same. As an example, both the Sony ILX511 and Hamamatsu S10420 have 2048 pixels, but difference in noise is 10x, and the detector sensitivities should be matched for the spectral range of interest. 5. Size matters. A larger optical bench offers higher resolution and better stray light reduction due to its longer focal length compared to smaller benches. Then again, the application requirements will ultimiately determine the trade offs on size and performance. 6. Some systems are designed to work only with a fiber optic probe. The coupling loss is typically ~50% from fiber end A to fiber end B, so unless necessary it should be reconsidered in favor of direct sampling when working with weak signals. 7. Sensitivity is the smallest detectable change in a relative signal. More difficult to specify is the lowest detectable amount of light or how many photons are needed for the detector electronics to record a change. Careful consideration should be given to the light intensity of a light source and the coupling efficiency. Furthermore, these parameters are all wavelength-dependent. 8. Most customers do not think they have much choice when selecting wavelength range and chose based on standard ranges offered by most manufacturers. As BaySpec manufacturers the gratings in-house, we have total control over the wavelength range design and can offer a customized range that will optimize the resolution over the range of interest. 9. Visualizing, processing and managing spectroscopy data is an important consideration when considering software package. An open system is necessary for most OEM applications, allowing the user to have control of method development, building libraries while providing a full software development kit with dll for modularization of code, code reuse, efficient memory usage, and reduced disk space. 10. Design of Engineering (DOE) is an important consideration when considering an OEM spectrometer manufacturer. All matters related to the final product use should be “designed in” from optics, mechanics, electronics and software for its intended use. The End of Life (EOL) should also be considered particularly for field-based industrial applications. BaySpec’s years of experience in optical design and broad technology manufacturing platform allow for optimized solutions for performance, reliability and price. With over 35,000 spectral engines of all types in the field representing billions of device hours. For more information, please contact BaySpec at +1(408)512-5928 or info@bayspec.com.

(a). Display Spectral Resolution: decimal points in the displayed wavelength value. We have 3 decimals in nanometer, which is 1 picometer (pm) resolution for displayed wavelength value.

(b). Readout Spectral Resolution: this is the minimum value of the wavelength variation which can be detected and reported by this device. For example, If you input a tunable laser signal to the FBGA and tune the laser wavelength by 1pm step, you will see the FBGA reported wavelength value following the tunable laser with each 1pm step.

(c). Physical Wavelength Resolution: this is the minimum wavelength spacing between two signal peaks which can still be distinguished as two peaks.

Normally, the physical wavelength resolution is not important in FBGA application. The most important thing in FBGA application is the readout spectral resolution. We have 1pm readout spectral resolution in our FBGA products and which is achieved by a special arithmetic in the firmware.

OSNR = 10 × log10[P(signal)/P(noise)]

In practice, we approximate P(signal) = P(mixed) – P(noise) since the clean optical signal is not obtainable, where P(mixed) is the total power measured at the corresponding channel wavelength. For detailed OSNR measurement, please refer to OSA documents.

The above principle requires an optical channel performance monitor (OCPM) with the following features:

1) fast response time

2) stable wavelength accuracy

3) ability to measure the whole spectra, as a spectrometer would

4) on-board data processing capacity

- Operating wavelength range

- Input power

- Required gain

- Noise figure

- Operating wavelength range

- Total input power

- Channel numbers

- Required gain

- Gain flatness

- Noise figure